How Michael Roark constructed Grenada’s IT server farm in South Florida

By Katelin Stecz

Contrary to its name, the cloud isn’t some magical place in the sky where every picture of your family is stored. It’s a network of servers very much located on planet Earth, and those metal boxes of integrated circuits and microchips usually reside in inconspicuous, modern-looking buildings called data centers.

Data centers are famously, or rather infamously, huge energy guzzlers. According to the U.S. Department of Energy, data centers account for about 2 percent of the country’s total electricity use, much of it consumed to keep the centers cool. That’s about as much as the total electrical consumption of South Dakota, Montana, Wyoming, and Idaho combined.

With increasing demand for more data, more data centers are needed. The problem is how to meet that demand with less impact on the planet’s carbon output.

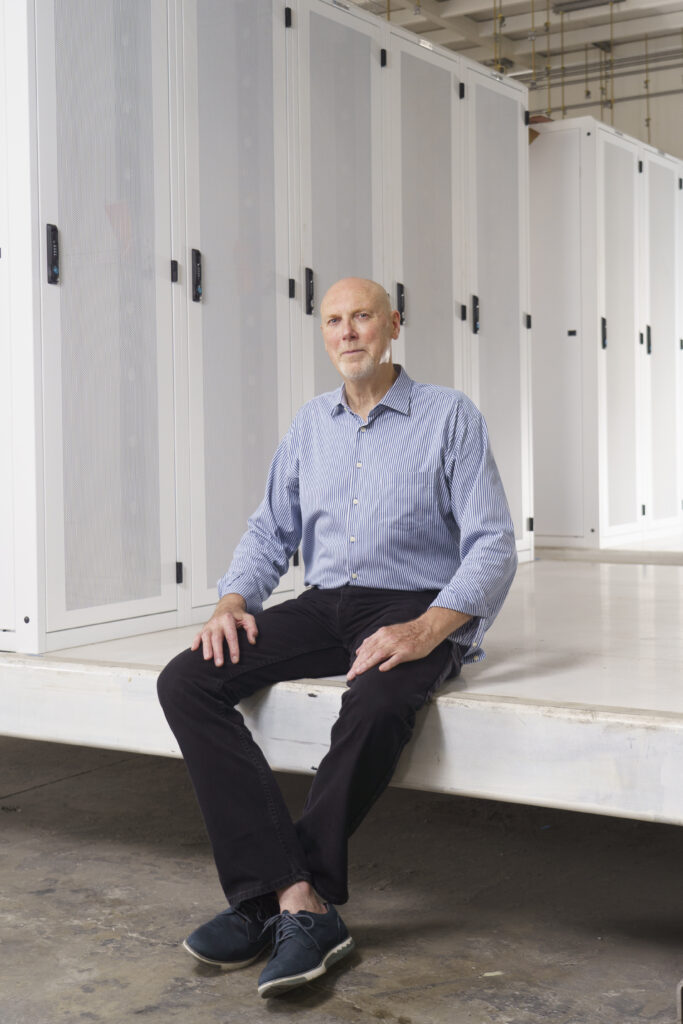

Michael Roark, CEO and founder of iM Data Centers, is working on the answer. Roark first dipped his toes in the data center industry with his construction company, M K Roark Inc., back in the 1990s. After two decades of constructing and eventually owning and operating colocation data centers, Roark realized a more cost-effective and sustainable way to build and operate them.

In 2014, Roark founded iM Data Centers. The idea was to use an assembly line, factory-based, prefabricated approach. This allowed iM to create much smaller, energy efficient data center “units.” Instead of large sprawling data centers that waste energy and cost more to cool, iM constructed compact, modular data centers, customizable for small users like hospitals, universities, or corporations.

“These are both greener and cheaper than traditional ones,” says Roark, a longtime naturalist, avid rock climber, and coauthor of “Greener Data: Actionable Insights from Industry Leaders.” By building small, modular units, “You can limit size to need, so you can control energy use,” he says. “This is especially true compared to retrofitting a building, but even compared with new ones from the ground up.” The welded steel units are also less expensive to install than building from scratch on-site and contain their own cooling and energy backup systems; iM’s inventive overhead “chill beams” save energy by directing cool air to servers based on their temperature.

The standard size for an iM single module unit is 50’x12’x12’ (600-square-feet); they are typically delivered in two pieces, each about the size of the standard TEU container that is stacked on cargo ships or put on flatbed trucks or rail cars. Customers can combine as many modules as needed to fulfill their needs.

That customization and low-energy use is what sold the governments of Grenada, St. Lucia, and St. Vincent on Roark’s units, which are also built to withstand category-5 hurricanes.

In 2021, iM built a data center for joint use by the three countries, a customized 48’x24’x12’ data center for installation on a ridge line outside Grenada’s capital, St. George’s. Manufactured in the iM plant northwest of Miami (the firm is headquartered in Ft. Lauderdale) and delivered by ship via Port Everglades, the data center had to be divided into four segments due to the steep hairpin turns on the road from the Port of Grenada to the site.

The new enterprise-class Edge data center is now part of the Caribbean Regional Communications Infrastructure Program (CARCIP), undertaken by Digicel Group and supported by the World Bank to expand broadband and backbone network infrastructure across the region. The facility is designed to serve regional governments with the idea of migrating all their IT services there over time, as well as to provide colocation to serve local businesses with lower latency times so they no longer have to shuttle data over a series of subsea cables.

Despite the onset of COVID while the modular units were being shipped to Grenada, the required site improvements were completed within a two-month period in preparation for their arrival, including diverse fiber backbone builds, utility power connections, and flat slabs for the data center and generators. Once iM’s crew was on the island, the entire installation and facility turn-up was completed in 18 days. Excluding constraints placed on the process by the COVID-19 crisis, the entire timeline from contract to data center commissioning was less than four months.

“There is an exponentially increasing need for data centers because there is an exponentially increasing production of data,” says Roark. “We have to keep up with digital infrastructures, especially in remote areas.” Roark also believes that climate change is one of the most pressing issues the world faces, and that industry must reduce its carbon footprint. So, in creating iM, Roark sought out an environmentally conscious capital partner. He found one in Galway Sustainable Capital, which only funds companies focused on ESG (Environmental, Social, and Governance) and carbon-reduction initiatives.

Furthering its climate-conscious mission, iM also provides free website hosting for nonprofit organizations involved in environmental sustainability, and carves out 5 percent of its corporate profit to invest in sustainability initiatives. The firm recently joined the Infrastructure Masons Climate Accord (ICA), a global nonprofit led by industry giants dedicated to reducing industry-wide carbon emissions.

“When you’re building something on site, even for a 10,000-square-foot data center, you’re easily producing 150 tons of embodied carbon,” says Tom Elowson, who works in iM’s data center creation and acquisition division. “When we manufacture one, it’s much less.”